Erosion and Wear of Elbows of Natural Gas Gathering and Transportation Pipelines

The background and significance

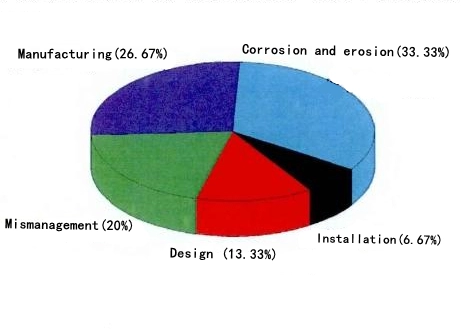

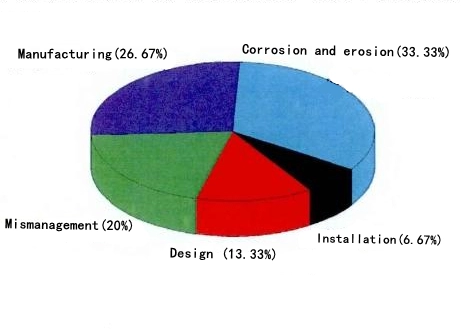

Since the 1990s, with the rapid development of China's national economy, the natural gas pipeline industry has also developed rapidly. As natural gas is transported in the pipeline, the entrained tiny solid particles will cause erosion and wear of the pipeline, and the corrosive composition carried will aggravate the erosion and wear, resulting in a decrease in the thickness of the inner wall of the pipeline, all of which in turn cause the pipeline to fail; safety hazards and economic losses are caused, which attracts considerable attention. Figure 1-1 shows the causes of explosions and serious accidents in petrochemical companies' I, II and III pipelines. From the figure, it can be found that the proportion of accidents caused by corrosion and erosion is the highest.

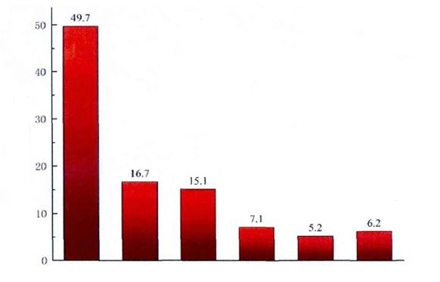

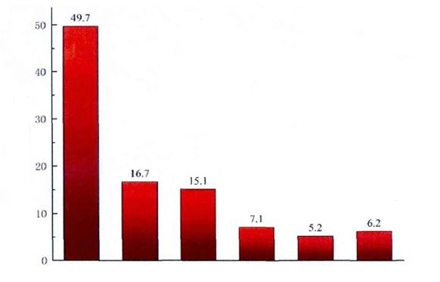

In addition, accident investigations and statistics on gas pipelines under the jurisdiction of the organization from 1970 to 2004 were conducted, and the pipeline with a length of 2.77×10km was investigated. There were a total of 1,123 accidents. Figure 1-2 shows that the proportion of accidents caused by corrosion and erosion is also high. Therefore, it is imperative to study the erosion and wear in natural gas pipelines.

Main reasons for accidents of gas pipelines

Figure 1-2 Investigation data on the causes of accidents of gas pipelines

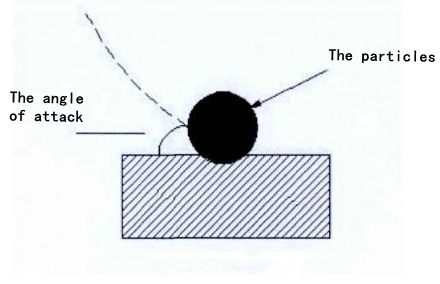

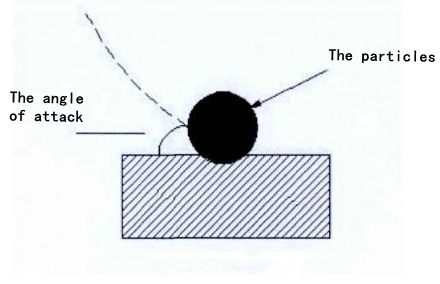

Wear caused by erosion refers to abrasion generated by the interaction of a solid surface and a fluid containing solid particles with a certain speed. At present, scholars generally believe that wear is related to micro cutting, deformation cutting and fatigue wear mechanisms. Two commonly used concepts in wear caused by erosion include the angle of attack and the collision velocity. The angle of attack refers to the angle between the incident trajectory of the erosive particles and the surface of the eroded target, as shown in the Figure 1-3. The collision velocity refers to the instantaneous velocity when the particles collide with the target.

Figure 1-3 The schematic diagram of wear caused by erosion

The natural gas gathering and transportation pipeline refers to the pipeline connecting the wellhead and centralized processing station. Since the natural gas extracted from the gas reservoir has not been purified, it often contains solid impurities such as iron filings, sand, cement, etc. The particle diameter is mainly between 30 and 50 meshes; wear and corrosion are extremely serious. At the same time, as the weak link in the overall pipeline, the inner wall of the elbow is directly impacted by solid particles; its wear is more serious compared with the other parts. According to field experience and data, the erosion and wear rate of the elbow is 50 times higher than that of the straight pipe. The influence on the wall of the elbow is often greater than that of the straight pipe. There was even literature saying that the probability of erosion and wear failure of an elbow in a natural gas station in Xinjiang is about 70 times higher than that of ordinary straight pipes. The physical erosion and wear of natural gas gathering and transportation pipelines is shown in the Figure 1-4. It can be seen from the figure that the wear perforation position is close to the area near the exit of the elbow.

Figure 1-4 Physical erosion and wear of natural gas gathering and transportation pipelines

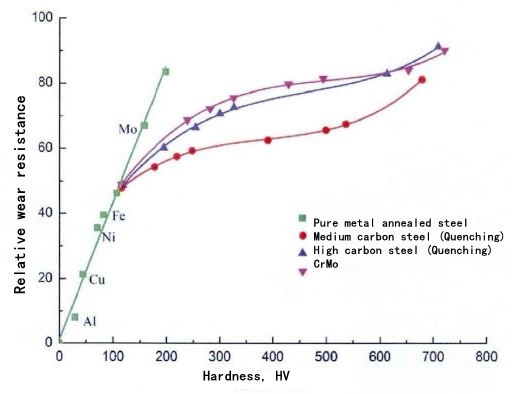

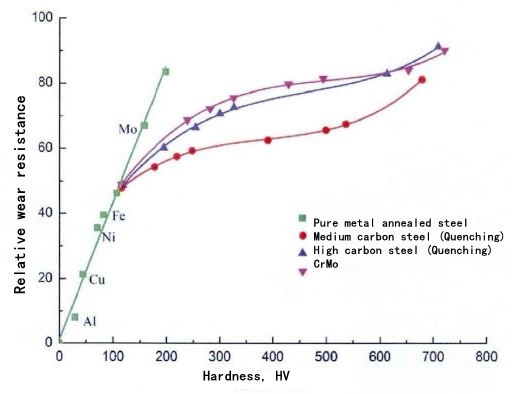

It can be known from the basic theory of wear that the most important factors affecting the quantities of wear are the material properties of the target and physical properties of the particles. J.Murry pointed out that in the wear process, hardness is the most important parameter, which controls the depth of hard particles penetrating into the soft surface. Figure 1-5 shows the relationship between the relative wear resistance of metals and their hardness.

Figure 1-5 The relationship between relative wear resistance and hardness of metals

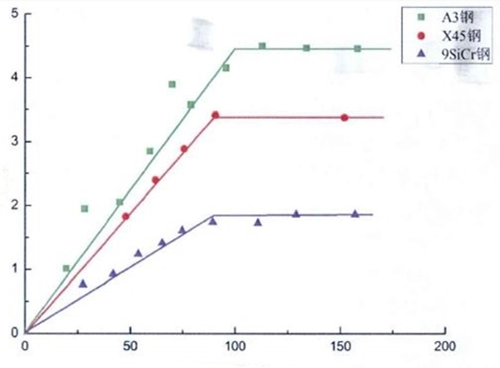

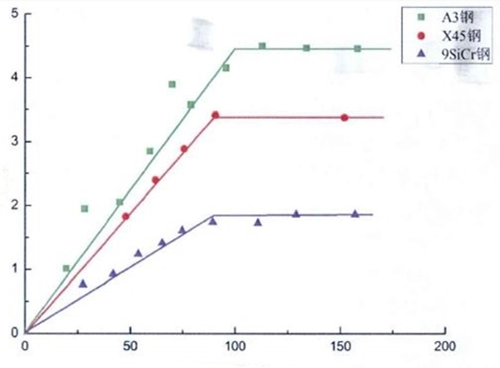

At the same time, the wear rate of steel is also closely related to the size of abrasive particles. From Figure 1-6, it can be seen that the wear rate of general metals increases with the increase of the average size of abrasive particles, but the wear rate no longer increases after the abrasive particles reach a certain critical point. The critical size of abrasive particles varies with the properties of the metal. Therefore, two ways to effectively reduce the wear rate of the elbow are to increase the hardness of the material and reduce the diameter of the impurities in the pipeline, the latter of which is limited by the performance of the separator. As for elbows of the natural gas gathering and transportation pipelines that have been built, the hardness of the pipes has been determined. Therefore, the task at this stage is how to control the occurrence of erosion and wear damage. Understanding and mastering the erosion and wear laws of elbows is the key to solve the wear problem of natural gas elbows, contributing to the development of the entire natural gas industry.

Figure 1-6 The relationship between the wear rate of steel and the size of abrasive particles

At present, although there are a large number of researches on erosion and wear mechanisms and experimental studies at home and abroad, there are few researches on the elbow of natural gas gathering and transportation pipelines. Therefore, it is necessary to study the erosion and wear of natural gas gathering and transportation pipeline elbows. The wear and corrosion of natural gas pipeline elbows is more complicated. First, the fluid in the pipe shows a gas-solid two-phase or even a gas-solid-liquid three-phase flow; second, there are interactions between gas and particles as well as particles and particles; finally, natural gas has its own nature that is more complicated, which brings certain difficulties to the study of erosion and wear rules and prevention of natural gas pipeline elbows.

This article focuses on the influence of factors such as the angle of attack and collision speed on the wear rate of the elbow by analyzing the wear rate prediction equation and movement characteristics of impurity particles in the elbow, and establish a wear rate prediction model that meets the field conditions. Predict the wear depth at different positions of elbows with different specifications according to the model. At the same time, the wear rate prediction equation can be used to determine the most severe partial wear area of the elbow. In the future design of the elbow, the overlap of the above-mentioned part with the heat affected zone of the weld can be avoided.

In summary, it is of great significance to study the erosion and wear laws of natural gas gathering and transportation pipeline elbows, and the research results have great practical engineering application value.

Since the 1990s, with the rapid development of China's national economy, the natural gas pipeline industry has also developed rapidly. As natural gas is transported in the pipeline, the entrained tiny solid particles will cause erosion and wear of the pipeline, and the corrosive composition carried will aggravate the erosion and wear, resulting in a decrease in the thickness of the inner wall of the pipeline, all of which in turn cause the pipeline to fail; safety hazards and economic losses are caused, which attracts considerable attention. Figure 1-1 shows the causes of explosions and serious accidents in petrochemical companies' I, II and III pipelines. From the figure, it can be found that the proportion of accidents caused by corrosion and erosion is the highest.

In addition, accident investigations and statistics on gas pipelines under the jurisdiction of the organization from 1970 to 2004 were conducted, and the pipeline with a length of 2.77×10km was investigated. There were a total of 1,123 accidents. Figure 1-2 shows that the proportion of accidents caused by corrosion and erosion is also high. Therefore, it is imperative to study the erosion and wear in natural gas pipelines.

Main reasons for accidents of gas pipelines

Figure 1-2 Investigation data on the causes of accidents of gas pipelines

Wear caused by erosion refers to abrasion generated by the interaction of a solid surface and a fluid containing solid particles with a certain speed. At present, scholars generally believe that wear is related to micro cutting, deformation cutting and fatigue wear mechanisms. Two commonly used concepts in wear caused by erosion include the angle of attack and the collision velocity. The angle of attack refers to the angle between the incident trajectory of the erosive particles and the surface of the eroded target, as shown in the Figure 1-3. The collision velocity refers to the instantaneous velocity when the particles collide with the target.

Figure 1-3 The schematic diagram of wear caused by erosion

The natural gas gathering and transportation pipeline refers to the pipeline connecting the wellhead and centralized processing station. Since the natural gas extracted from the gas reservoir has not been purified, it often contains solid impurities such as iron filings, sand, cement, etc. The particle diameter is mainly between 30 and 50 meshes; wear and corrosion are extremely serious. At the same time, as the weak link in the overall pipeline, the inner wall of the elbow is directly impacted by solid particles; its wear is more serious compared with the other parts. According to field experience and data, the erosion and wear rate of the elbow is 50 times higher than that of the straight pipe. The influence on the wall of the elbow is often greater than that of the straight pipe. There was even literature saying that the probability of erosion and wear failure of an elbow in a natural gas station in Xinjiang is about 70 times higher than that of ordinary straight pipes. The physical erosion and wear of natural gas gathering and transportation pipelines is shown in the Figure 1-4. It can be seen from the figure that the wear perforation position is close to the area near the exit of the elbow.

Figure 1-4 Physical erosion and wear of natural gas gathering and transportation pipelines

It can be known from the basic theory of wear that the most important factors affecting the quantities of wear are the material properties of the target and physical properties of the particles. J.Murry pointed out that in the wear process, hardness is the most important parameter, which controls the depth of hard particles penetrating into the soft surface. Figure 1-5 shows the relationship between the relative wear resistance of metals and their hardness.

Figure 1-5 The relationship between relative wear resistance and hardness of metals

At the same time, the wear rate of steel is also closely related to the size of abrasive particles. From Figure 1-6, it can be seen that the wear rate of general metals increases with the increase of the average size of abrasive particles, but the wear rate no longer increases after the abrasive particles reach a certain critical point. The critical size of abrasive particles varies with the properties of the metal. Therefore, two ways to effectively reduce the wear rate of the elbow are to increase the hardness of the material and reduce the diameter of the impurities in the pipeline, the latter of which is limited by the performance of the separator. As for elbows of the natural gas gathering and transportation pipelines that have been built, the hardness of the pipes has been determined. Therefore, the task at this stage is how to control the occurrence of erosion and wear damage. Understanding and mastering the erosion and wear laws of elbows is the key to solve the wear problem of natural gas elbows, contributing to the development of the entire natural gas industry.

Figure 1-6 The relationship between the wear rate of steel and the size of abrasive particles

At present, although there are a large number of researches on erosion and wear mechanisms and experimental studies at home and abroad, there are few researches on the elbow of natural gas gathering and transportation pipelines. Therefore, it is necessary to study the erosion and wear of natural gas gathering and transportation pipeline elbows. The wear and corrosion of natural gas pipeline elbows is more complicated. First, the fluid in the pipe shows a gas-solid two-phase or even a gas-solid-liquid three-phase flow; second, there are interactions between gas and particles as well as particles and particles; finally, natural gas has its own nature that is more complicated, which brings certain difficulties to the study of erosion and wear rules and prevention of natural gas pipeline elbows.

This article focuses on the influence of factors such as the angle of attack and collision speed on the wear rate of the elbow by analyzing the wear rate prediction equation and movement characteristics of impurity particles in the elbow, and establish a wear rate prediction model that meets the field conditions. Predict the wear depth at different positions of elbows with different specifications according to the model. At the same time, the wear rate prediction equation can be used to determine the most severe partial wear area of the elbow. In the future design of the elbow, the overlap of the above-mentioned part with the heat affected zone of the weld can be avoided.

In summary, it is of great significance to study the erosion and wear laws of natural gas gathering and transportation pipeline elbows, and the research results have great practical engineering application value.