Identification Methods of Seamless Steel Pipes and Welded Steel Pipes (Part Three)

Principles

Macroscopic identification

Observe the prepared steel pipe sample with the naked eye or a magnifying glass smaller than or equal to 10 times. If the welding is found, there are the complete welding morphology characteristics of the welded sea, fusion and base material zone. This means the steel pipe is welded steel pipe. If there is no weld, that means the steel pipe is seamless steel pipe.

Microscopic identification

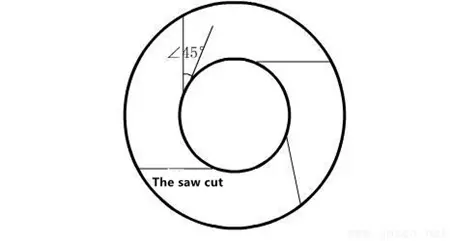

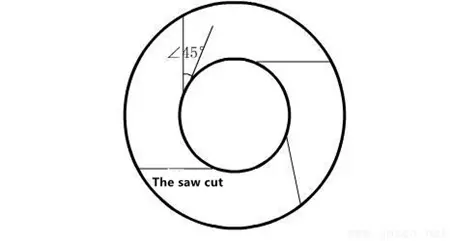

If it is difficult to identify macroscopically, use a metallographic microscope for microscopic identification. Adjust the optical path and magnification of the metallographic microscope. Start from a lower magnification, observing the entire cross-section. If there are signs of welded seams that are difficult to confirm, use higher multiples for further analysis and confirmation. According to whether there are welding structure characteristics, distinguish welded steel pipes from seamless steel pipes. Cold cut the complete cross section on the steel pipes and avoid the heat affected zone based on GB/T 13298. The steel pipe should be polished with full sections as much as possible. If the diameter of the steel pipe is large and the steel pipe cannot be polished with full sections, cut the cross section into several sections. The width of the saw cut should not be more than 2mm. Wire-electrode cutting is recommended. The saw cut and the included angle of the tangent line should not be greater than 45°so as to ensure that the welded seam checking is not missed. The schematic diagram of the saw cut and the steel pipe is shown in Figure 1.

Figure 1 The schematic diagram of the cutting angle

Structure display methods

The immersing methods

3% to 5% nitric acid-ethanol solution is recommended as the immersing agent. Other metallographic structure display agents can also be used. Evenly immerse or apply the prepared reagent on the surface to be inspected in a ventilated place at room temperature. The immersing time depends on the steel type and reagent. Rinse the cross section with clean water, ethanol and then use hot air to dry it quickly after corrosion.

The chemical deposition film method

When the film is formed, immerse the sample in the reagent in a ventilated place to observe the color of the sample. When the surface of the sample changes from yellow to blue, immediately take out the sample. Rinse the sample with water and ethanol, and quickly dry it with hot air.

Identification methods

Magnification

10x, 50x, 100x, 200x, 500x, etc. are all available, depending on the size of the tested sample and clarity of the microstructure. Whether or not the structure and type can be seen and the sample has been welded.

Macroscopic identification

After the above sample preparation, you can use a magnifying glass with a magnification smaller than or equal to 10 times to observe the sample, as it is shown in Figure 2. The center of the figure shows the macroscopic welding part.

Figure 2

Macroscopic identification

Observe the prepared steel pipe sample with the naked eye or a magnifying glass smaller than or equal to 10 times. If the welding is found, there are the complete welding morphology characteristics of the welded sea, fusion and base material zone. This means the steel pipe is welded steel pipe. If there is no weld, that means the steel pipe is seamless steel pipe.

Microscopic identification

If it is difficult to identify macroscopically, use a metallographic microscope for microscopic identification. Adjust the optical path and magnification of the metallographic microscope. Start from a lower magnification, observing the entire cross-section. If there are signs of welded seams that are difficult to confirm, use higher multiples for further analysis and confirmation. According to whether there are welding structure characteristics, distinguish welded steel pipes from seamless steel pipes. Cold cut the complete cross section on the steel pipes and avoid the heat affected zone based on GB/T 13298. The steel pipe should be polished with full sections as much as possible. If the diameter of the steel pipe is large and the steel pipe cannot be polished with full sections, cut the cross section into several sections. The width of the saw cut should not be more than 2mm. Wire-electrode cutting is recommended. The saw cut and the included angle of the tangent line should not be greater than 45°so as to ensure that the welded seam checking is not missed. The schematic diagram of the saw cut and the steel pipe is shown in Figure 1.

Figure 1 The schematic diagram of the cutting angle

Structure display methods

The immersing methods

3% to 5% nitric acid-ethanol solution is recommended as the immersing agent. Other metallographic structure display agents can also be used. Evenly immerse or apply the prepared reagent on the surface to be inspected in a ventilated place at room temperature. The immersing time depends on the steel type and reagent. Rinse the cross section with clean water, ethanol and then use hot air to dry it quickly after corrosion.

The chemical deposition film method

When the film is formed, immerse the sample in the reagent in a ventilated place to observe the color of the sample. When the surface of the sample changes from yellow to blue, immediately take out the sample. Rinse the sample with water and ethanol, and quickly dry it with hot air.

Identification methods

Magnification

10x, 50x, 100x, 200x, 500x, etc. are all available, depending on the size of the tested sample and clarity of the microstructure. Whether or not the structure and type can be seen and the sample has been welded.

Macroscopic identification

After the above sample preparation, you can use a magnifying glass with a magnification smaller than or equal to 10 times to observe the sample, as it is shown in Figure 2. The center of the figure shows the macroscopic welding part.

Figure 2

- The base material area

- The welded seam area

- The fusion area

Microscopic identification

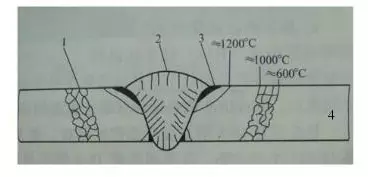

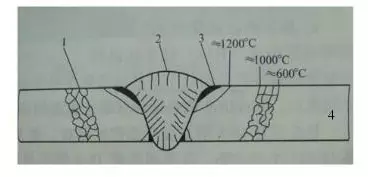

If no welded seam is found macroscopically, a microscope can be used for inspection. Hot-rolled band structure, twin structure and equiaxed grains have continuity for the microstructure which is not welded. The welded structure of steel pipes with welding is obvious. Stainless steel generally has four zones such as sensitization zones, welded zones, fusion zones and base metal zones. See Figure 3.

Figure 3 Stainless steel welding area

If no welded seam is found macroscopically, a microscope can be used for inspection. Hot-rolled band structure, twin structure and equiaxed grains have continuity for the microstructure which is not welded. The welded structure of steel pipes with welding is obvious. Stainless steel generally has four zones such as sensitization zones, welded zones, fusion zones and base metal zones. See Figure 3.

Figure 3 Stainless steel welding area

- The sensitization area

- The welding area

- The fusion zone

- The base material area

Characteristics of welding structure

Metallographic structure reference picture: The welded structure has obvious fusion zones. There is a structure of cooling crystallization at the weld, and the crystal generally has directionality. The structure of the heat-affected zone near the base metal of the welded seam is characterized by carbide precipitation or coarse structure.

Carbon steel welding structure

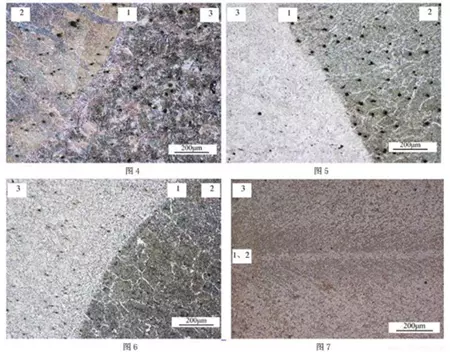

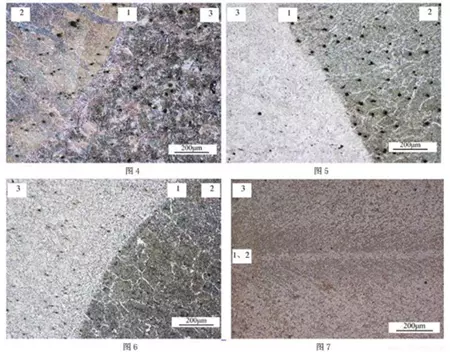

The magnification is 100 times, and check Figure 4-7.

Metallographic structure reference picture: The welded structure has obvious fusion zones. There is a structure of cooling crystallization at the weld, and the crystal generally has directionality. The structure of the heat-affected zone near the base metal of the welded seam is characterized by carbide precipitation or coarse structure.

Carbon steel welding structure

The magnification is 100 times, and check Figure 4-7.

- The fusion zone

- The welding area

- The heat affected zone

Stainless steel welding structure

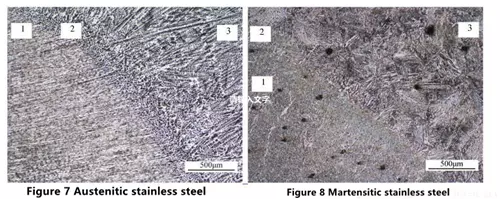

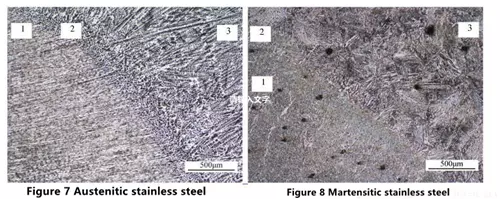

The magnification is 50 times, and check Figure 7-8.

Figure 7 & 8

The magnification is 50 times, and check Figure 7-8.

Figure 7 & 8

- The welded area

- The fusion zone

- The base material area

References

Analysis of how to correctly distinguish between welded steel pipes and seamless steel pipes edited by Ling Chen and Wu Peng

The new development of welded steel pipe technology edited by Wang Xiaoxiang

Development and application of finite element models of seamless steel pipes in tension reducing process edited by Yu Hui, Du Fengshan and Wang Feixue.

Welding problems of porosity defects in seamless steel pipes with large diameters and thick walls edited by Liu Feng, Wang Shuaiwei and Chen Lei

Analysis of how to correctly distinguish between welded steel pipes and seamless steel pipes edited by Ling Chen and Wu Peng

The new development of welded steel pipe technology edited by Wang Xiaoxiang

Development and application of finite element models of seamless steel pipes in tension reducing process edited by Yu Hui, Du Fengshan and Wang Feixue.

Welding problems of porosity defects in seamless steel pipes with large diameters and thick walls edited by Liu Feng, Wang Shuaiwei and Chen Lei