The Water Hammer Protection of Long-distance Pressure Sewage Pipeline Engineering (Part One)

Abstract: In the long-distance pressure sewage pipeline project, the water hammer protection measures play a vital role in ensuring the safe and stable operation of the pipeline. A sewage pipeline project with long-distance, great flow, low head in Nanjing is taken as an example in this article; the Bentley HAMMER V8i the water hammer simulation software is used to analyze the characteristics of the water hammer when the pump is stopped, and a two-stage slow-closing check valve is selected combined with the gas injection micro-exhaust valve protection. It is found that adopting the water hammer protection measures can significantly reduce the positive pressure of the water hammer and eliminate its negative pressure, which is conducive to the safe and stable operation of the pipeline.

1. The overview of the project

A sewage pipeline project in Nanjing City needs to transfer sewage from a certain area to a sewage treatment plant through a sewage pumping station. The total design scale of the project is 200,000 m3/d, and the sewage transportation distance is 10 km. A total of two sewage pipelines are designed. The left pipeline is from the sewage pumping station to the sewage treatment plant and a DN1200 pressure pipe with a length of 10 km is used; the right pipeline is for the needs of the local area. After the high-speed train section, an energy dissipation well is set up to release a DN1200 pressure sewage pipe into a d1800 gravity pipe. Therefore, a DN1200 pressure pipe (from the sewage pumping station to the pressure release point) and a d1800 gravity pipe (from the pressure release point to the sewage treatment plant) are adopted for the right pipeline. The length of the pressure pipe is 7.5 km, and the hydraulic slope of the pipeline is 1.3‰. In this project, a ductile iron pipe is selected for the sewage pressure pipe, with a design flow of 1.5m3/s, a flow rate of 1.33m/s, and a pipe wall thickness of 13.6 mm. The pipeline is coated with polyurethane for anticorrosion, and the surface is sandblasted or shot blasted. The thickness of the inner coating is not less than 900μm, and that of the outer anticorrosion coating is not less than 700μm. In this project, 4 submersible sewage pumps including the spare were installed inside the pumping station. Each pump has a rated flow of 1800m3/h, a design head of 32 m, a rated shaft power of 175kW, motor power of 220kW, a rated efficiency of 77% and a speed of 980r/min. The bottom elevation of the sump is -4.52 m; the highest point of the engineering design pressure pipe is 4.58 m; the static head is 9.1 m, and the head loss in the pumping station is 4.5 m, which is a typical sewage pipeline project with long-distance, great flow, and low head.

2. Model establishment and basic parameters of the the water hammer

2.1 Establishment of the model of the water hammer

In view of the great harm caused by the water hammer, the water hammer protection measures need to be taken, and the water hammer calculations can provide a theoretical basis for subsequent the water hammer protection. The calculated maximum internal water pressure can be used as the basis for designing or checking the strength of the pipeline, and the calculated minimum internal water pressure can provide a basis for preventing negative pressure in the pressure pipeline. Combined with the project data, the Bentley HAMMER V8i the water hammer simulation software was used to establish a calculation model for the the water hammer.

2.2 Basic parameters of the water hammer

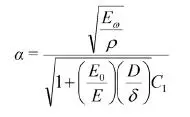

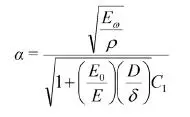

The wave velocity of the water hammer is an important parameter for analyzing the water hammer problems, which is mainly affected by many factors such as pipe diameters, pipe wall thickness and water elastic coefficient. The calculation formula of wave velocity of the water hammer is as follows:

(1)

(1)

In this formula, is the propagation velocity of sound waves in water, with a value of 1435m/s; D is the inner diameter of the pipe, and DN1200 ductile iron pipe is used in this project; δ is the wall thickness of the pipe, with a value of 13.6 mm; E0 is the elastic coefficient of water, with a value of 2.1×108kg/m2; C1 is the parameter of different wall thickness and support methods. In this project, C1 is equal to 1-μ2, 1-0.32 and 0.91. The wave velocity of the water hammer is 1105m/s based on the formula (1). The calculation formula of phase length of the water hammer is as follows:

is the propagation velocity of sound waves in water, with a value of 1435m/s; D is the inner diameter of the pipe, and DN1200 ductile iron pipe is used in this project; δ is the wall thickness of the pipe, with a value of 13.6 mm; E0 is the elastic coefficient of water, with a value of 2.1×108kg/m2; C1 is the parameter of different wall thickness and support methods. In this project, C1 is equal to 1-μ2, 1-0.32 and 0.91. The wave velocity of the water hammer is 1105m/s based on the formula (1). The calculation formula of phase length of the water hammer is as follows:

(2)

(2)

In the formula, L is the total length of the pipeline (m); α is the wave velocity of the water hammer (m/s). The lengths of the two pipe sections are 7500 m and 10000 m respectively, and the phase lengths of the water hammer of the two pipe sections are 13.5s and 18.0s respectively.

3. Calculation results of steady-state the water hammer and the stopped pump

3.1 Steady-state calculation results

(1) From the pressure release section to the pumping station, the lowest point in the pipe is K4 plus 797, and the elevation is -8.5 m. At this time, the steady-state pressure head is 17.61 m; at the point of K0 plus 009, the steady-state highest pressure water head is 19.30 m. At this time, the steady-state water head is 19.30 m, and the pipe elevation is 0 m; at the end of the pipeline, the steady-state pressure head is 0.12 m, and the steady-state water head is 4.50 m; the pipe elevation is 4.38 m.

(2) From the pumping station to the sewage treatment plant section, the lowest point of the pipe elevation is K4 plus 797, and the elevation is -8.5 m. At this time, the steady-state pressure head is 20.29 m; at the point of K0 plus 009, the steady-state highest pressure water head is 22.01 m. At this time, the steady-state water head is 22.01 m, and the pipe elevation is 0 m; at the end of the pipeline, the steady-state pressure head is 0.50 m, and the steady-state water head is 3.50 m; the tube elevation is 3 m.

3.2 Calculation results of the water hammer of stopped pumps

(1) Under unprotected conditions, the the water hammer calculation results of the pump station to pressure release point section showed that the maximum pressure head of the entire pipeline appeared at the point of K0 plus 319, which is 142.30 m and about 7 times higher than the rated pressure of the pump outlet. It is much higher than 1.5 times the pressure specified in the Design Specifications of Pumping Stations in GB 50265-2010. Therefore, if there are no protective measures, when the pump is stopped due to an accident, the positive pressure of the pipeline will be too high, causing the pipeline to burst easily. The minimum pressure head appeared at the point of K4 plus 798, which is -3.61 m. The negative pressure value is high, and the maximum air volume is 89770L, which is prone to the water hammer, and is not conducive to the safe and stable operation of the pipeline.

(2) Under unprotected conditions, the the water hammer calculation results of the pumping station-sewage treatment plant section showed that the maximum pressure head of the entire pipeline appears at point K0 plus 319, which is 144.45m and about 6.4 times the rated pressure of the pump outlet. The smallest pressure head appeared at the point of K6 plus 172, which is -4.24 m, and the negative pressure value was relatively high. The maximum air volume is 37974L, which is prone to the the water hammer and not beneficial to the safe and stable operation of the pipeline.

2. Model establishment and basic parameters of the the water hammer

2.1 Establishment of the model of the water hammer

In view of the great harm caused by the water hammer, the water hammer protection measures need to be taken, and the water hammer calculations can provide a theoretical basis for subsequent the water hammer protection. The calculated maximum internal water pressure can be used as the basis for designing or checking the strength of the pipeline, and the calculated minimum internal water pressure can provide a basis for preventing negative pressure in the pressure pipeline. Combined with the project data, the Bentley HAMMER V8i the water hammer simulation software was used to establish a calculation model for the the water hammer.

2.2 Basic parameters of the water hammer

The wave velocity of the water hammer is an important parameter for analyzing the water hammer problems, which is mainly affected by many factors such as pipe diameters, pipe wall thickness and water elastic coefficient. The calculation formula of wave velocity of the water hammer is as follows:

(1)

(1)In this formula,

In the formula, L is the total length of the pipeline (m); α is the wave velocity of the water hammer (m/s). The lengths of the two pipe sections are 7500 m and 10000 m respectively, and the phase lengths of the water hammer of the two pipe sections are 13.5s and 18.0s respectively.

3. Calculation results of steady-state the water hammer and the stopped pump

3.1 Steady-state calculation results

(1) From the pressure release section to the pumping station, the lowest point in the pipe is K4 plus 797, and the elevation is -8.5 m. At this time, the steady-state pressure head is 17.61 m; at the point of K0 plus 009, the steady-state highest pressure water head is 19.30 m. At this time, the steady-state water head is 19.30 m, and the pipe elevation is 0 m; at the end of the pipeline, the steady-state pressure head is 0.12 m, and the steady-state water head is 4.50 m; the pipe elevation is 4.38 m.

(2) From the pumping station to the sewage treatment plant section, the lowest point of the pipe elevation is K4 plus 797, and the elevation is -8.5 m. At this time, the steady-state pressure head is 20.29 m; at the point of K0 plus 009, the steady-state highest pressure water head is 22.01 m. At this time, the steady-state water head is 22.01 m, and the pipe elevation is 0 m; at the end of the pipeline, the steady-state pressure head is 0.50 m, and the steady-state water head is 3.50 m; the tube elevation is 3 m.

3.2 Calculation results of the water hammer of stopped pumps

(1) Under unprotected conditions, the the water hammer calculation results of the pump station to pressure release point section showed that the maximum pressure head of the entire pipeline appeared at the point of K0 plus 319, which is 142.30 m and about 7 times higher than the rated pressure of the pump outlet. It is much higher than 1.5 times the pressure specified in the Design Specifications of Pumping Stations in GB 50265-2010. Therefore, if there are no protective measures, when the pump is stopped due to an accident, the positive pressure of the pipeline will be too high, causing the pipeline to burst easily. The minimum pressure head appeared at the point of K4 plus 798, which is -3.61 m. The negative pressure value is high, and the maximum air volume is 89770L, which is prone to the water hammer, and is not conducive to the safe and stable operation of the pipeline.

(2) Under unprotected conditions, the the water hammer calculation results of the pumping station-sewage treatment plant section showed that the maximum pressure head of the entire pipeline appears at point K0 plus 319, which is 144.45m and about 6.4 times the rated pressure of the pump outlet. The smallest pressure head appeared at the point of K6 plus 172, which is -4.24 m, and the negative pressure value was relatively high. The maximum air volume is 37974L, which is prone to the the water hammer and not beneficial to the safe and stable operation of the pipeline.